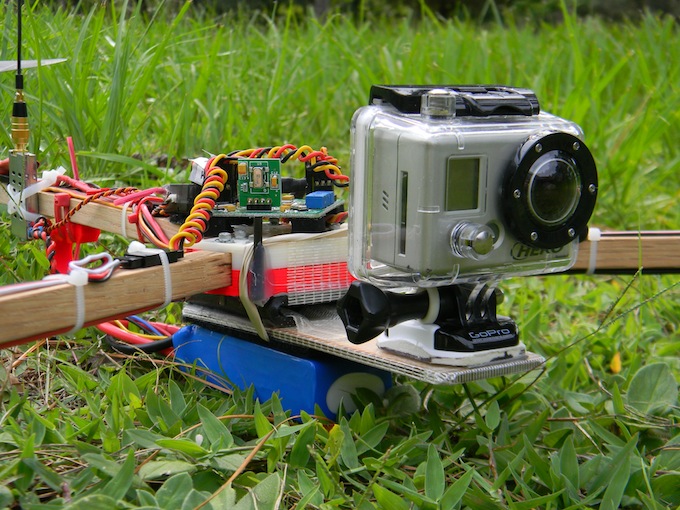

Ever since I have used a GoPro on my tricopter I have been trying to eliminate the vibrations that the motors and propellers cause. I have balanced all the motors and propellers to the best of my abilities but that is proven to not be enough on its own. Now I need a better vibration absorbing camera mount.

My previous mount used this foam that I received as a gift from FPVStockholm, it worked very well and eliminated a lot of the vibrations. The only issue I had was when I wanted some more. The material was very hard to find and when I did find it, it was very expensive. The foam was also held together with hot glue since it was not double sided. After a while of use it was beginning to fall apart. So, I needed to find a more suitable material.

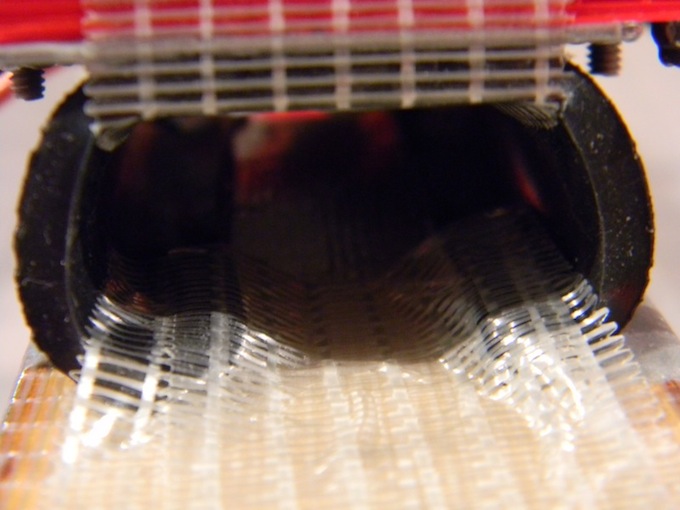

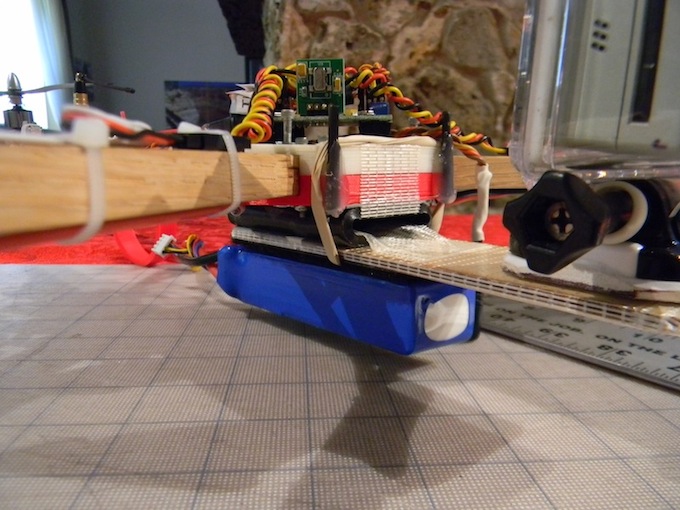

I found this vibration absorbing rubber instead, it is less expensive and is readily available. Above, is my first attempt of using this rubber and double sided tape. It did not work very well and the majority of vibrations slipped right through it, as you can see in the video at the end of this post. Now I will show you how I built my current working vibration mount.

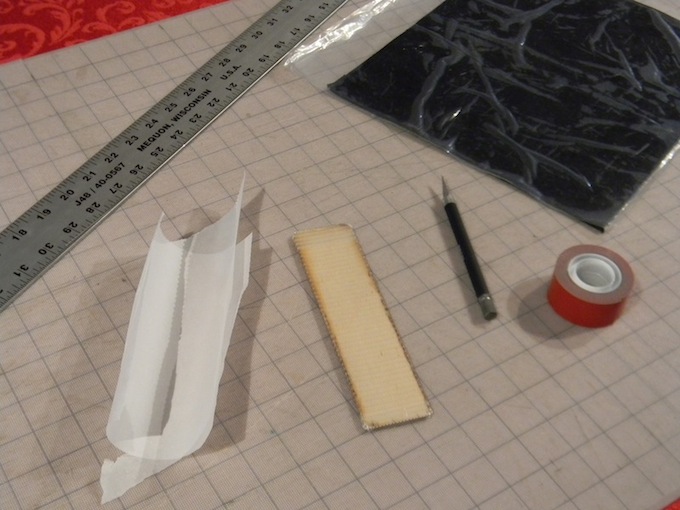

Here are the materials and tools:

Wax Paper

1.75″x7″ plywood

3M Heavy Duty Double Sided Tape (I found mine at Walmart)

Exacto Knife

Measuring Stick

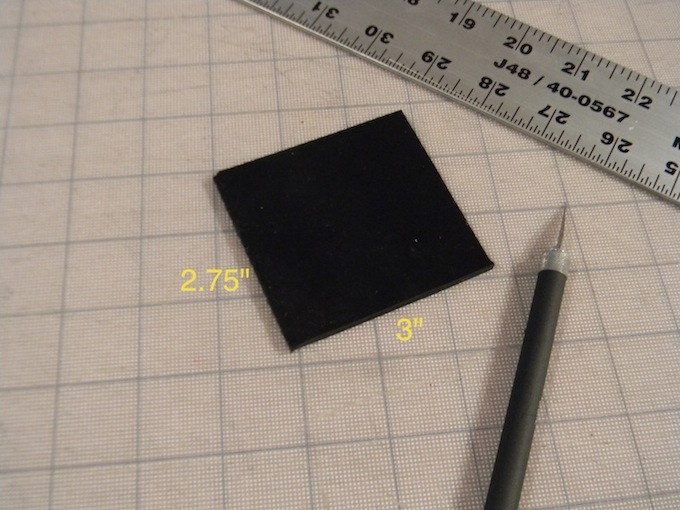

I measured and cut out a 2.75″x3″ section of the rubber

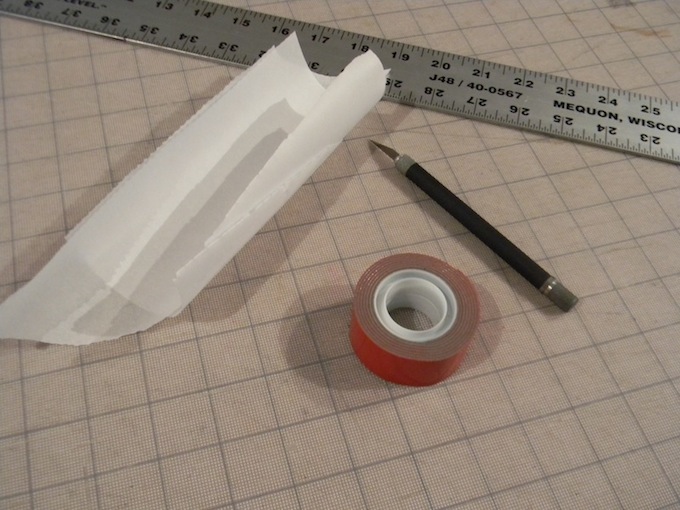

Then I got the double sided tape and wax paper for the next step.

I laid down a section of the double sided tape on a piece of wax paper so that I could measure and cut it without having it stick to my work surface and so it didn’t loose its adhesive.

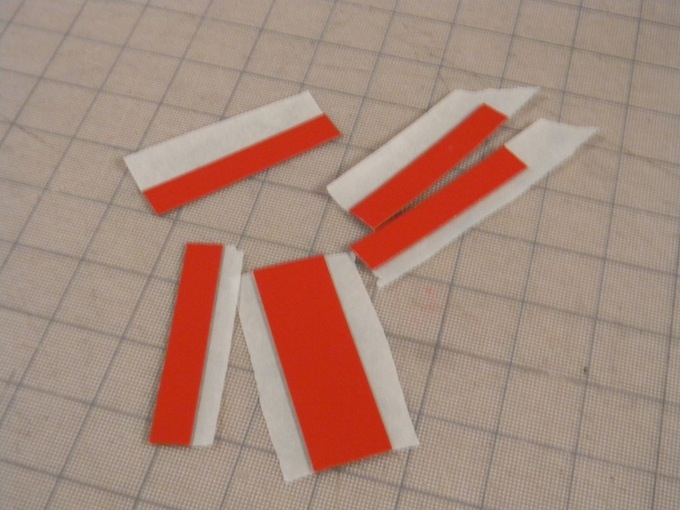

I cut the piece of tape to make four .5″x3″ (I only used 3 of these) and one 1″x3″ pieces of tape.

I put two of the .5″x3″ pieces of tape on the edges of the rubber, parallel with the 3″ sides.

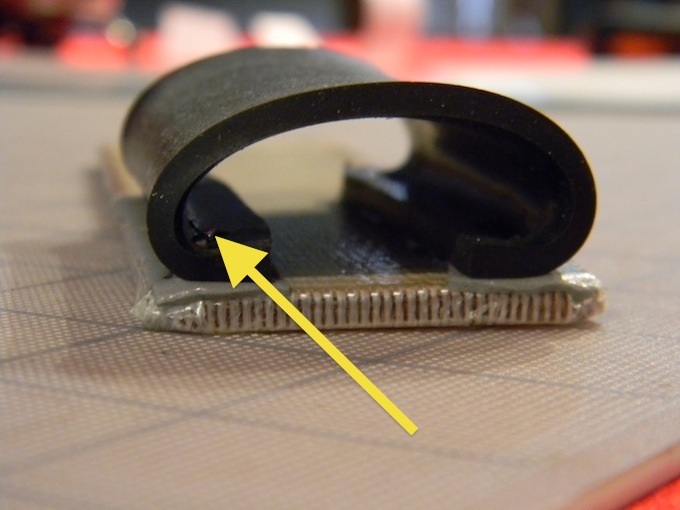

Then, I stuck these edges to the plywood in a loop like in the picture above. I reenforced the tape with four staples on each corner, the arrow is pointing at one of them.

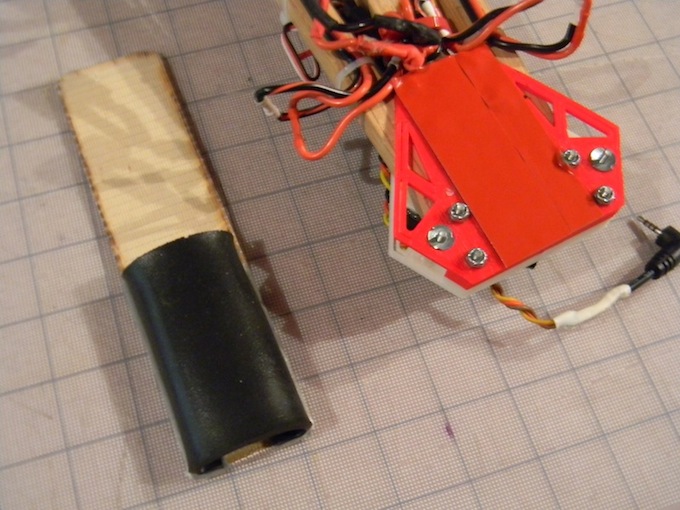

I put the 1″x3″ and .5″x3″ pieces of tape in the middle of the body and then pealed off the top cover from the tape and stuck the plywood with the rubber to the body.

I reenforced the connection with some heavy duty packing tape.

Finally, I put a rubber band in the front to restrict the movement of the shock absorbing rubber. The battery is attached with velcro to the bottom of the plywood as to act as weight so that the whole mount will maintain stable.

httpvh://www.youtube.com/watch?v=bGORL0GP-5M&feature=youtu.be